AAMA Certified Architectural & Aluminum Extrusion Finishing

We have installed a non-chrome, multi-step pretreatment process to allow us to achieve AAMA architectural grade certified finishes for aluminum extrusions. Our facility can process aluminum extrusions up to 22’ in length. Once the substrate has been pretreated, a wide selection of fluoropolymer finish coatings is available to satisfy the requirements of the customer.

Selection of Coatings

- Urethane

- Epoxy’s

- Polyurethane

- Metallic’s

- Polyesters

- Special Effects

- Hybrids

- Dry Film Lubricants

- Vinyl

- Arma Coatings

- Enamels Water and Solvent

- 3M Scotchkote

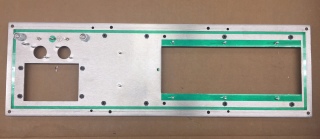

Custom and consistent solutions for precision masking of parts

Our team is experienced at precision masking of parts so that the final product meets client specifications. For high volume manufacturing, we are capable of developing masking templates to provide quick and consistent part masking, helping to reduce final product costs to the customer. Custom solutions, engineering ingenuity and expertise allow us to produce dependable, quality results for your unique requirements.

Our team is experienced at precision masking of parts so that the final product meets client specifications. For high volume manufacturing, we are capable of developing masking templates to provide quick and consistent part masking, helping to reduce final product costs to the customer. Custom solutions, engineering ingenuity and expertise allow us to produce dependable, quality results for your unique requirements.

Speciality Coatings

We offer our customers a wide variety of finishes, including translucents, vein colors, wrinkles and clear coats. Our network of coating suppliers enables us to provide a variety of finishes that are durable and, depending upon the application, specifically resistant to corrosion, chemicals, abrasion and impacts.

Color Consistency

Color consistency is critical with single surfaces, multiple panels or separate components. With the aid of sophisticated software, we evaluate color, gloss and film coatings for process and color variation. This allows us to calibrate color reproduction, control color proof quality and assure close tolerance in the finished product.

Color Matching

Professional Finishing has perfected the art of matching and repeating the production of any color. Whenever a customer places an order, we place the object under our spectrophotometer to capture the color values so that the final color falls within the appropriate parameters when we finish the product.

Color Charts

Rigorous technical and quality control

Every coating meets or exceeds requirements for any application, including military specifications. We measure film thickness to ensure precision and consistency. We check all colors with a spectrophotometer and we use a tri-gloss meter to ensure that the gloss meets manufactures specifications.